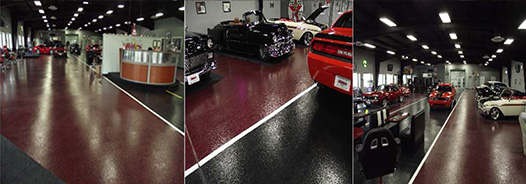

Project of the Month: Full Chip Floor, by Garage Logic

For this month's project, we take a closer look at a floor done by Garage Logic

Inc., of Bismarck, ND. Products used for this floor were Poly-350 basecoat, 1/4" vinyl

chips, and RG-80x Top Coat. The finished floor is 100% UV stable, and provides great abrasion

and chemical resistance along with a glossy finish. From prep to finished product, this

floor was completed in two days, including the different colors and striping. It just

goes to show what trained installers, backed by the finest materials Citadel can provide, can accomplish!

Great job Garage Logic!

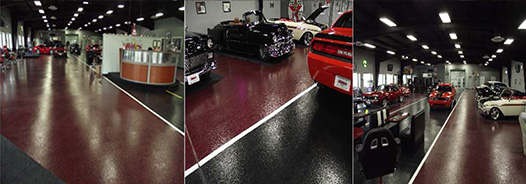

Floor Installation Process

- Mechanically ground the surface to a salt and pepper profile.

- Applied Poly-350 base coat, tinted black, to the outer 27' on both sides and broadcasted red and black chip to full rejection.

- Recovered the loose chip to save and scraped the remaining chip flat. Applied RG-80x topcoat just in outer area to lock the chips down.

- Applied 3" tape on the floor for the white boarder and yellow center line to "build the road". Applied Poly-350 base coat tinted black and broadcast black chip to rejection for the road.

- Recovered the loose chip to save and scraped the remaining chip flat. Applied RG-80 topcoat.

- The white outer lines and the center yellow lines were all very carefully cut in and full chip broadcast into them.

- Scraped and vacuumed the lines and applied RG-80x just to the lines.

- The next day the entire area was scuff sanded, solvent wiped and a final application of RG-80x topcoat applied to tie the floor together.

Monthly Product Highlight: Ultra Hydro-Stop H2O

We have recently changed the packaging and product amounts for our moisture vapor

product Ultra Hydro Stop H2O. CFFS Ultra-Hydro Stop H2O Primer&tm; is now provided in

proportioned kits containing resin and hardener. No water is sent with the kit, clean water is

to be added at the jobsite. The entire contents of the Hardener (Part B) is emptied into the

Resin (Part A) container and mixed with a drill for 2-3 minutes. After the resin and hardener

are combined, clean water (52 oz) is added slowly, under agitation, until a uniform mixture

is achieved. No induction time is needed the material is ready to use immediately. Below is

a chart showing the kit amount of Part A and Part B, along with the amount of water to be

added in the field. When all 3 parts are combined, you are left with 1.5 gallons of product. No

changes to product performance and is still Capable of holding back up to 12 lbs. of MVT (two

coats) This primer has excellent adhesion to moisture laden concrete slabs. Ultra-Hydro Stop

H2O Primer can be applied to concrete as early as 48 hours after placement, reducing

job-site downtime and delays in production. For Application, use a Roller, brush or a 1/8"

notch squeegee to spread the material out over the surface at a spread rate of 250 sf/gallon.

THIS SPREAD RATE MUST BE PRECISELY MET FOR THE PRODUCT TO FUNCTION PROPERLY.

Do not allow the material to pool or fill in control joints or a soft cured product may result.

| Part A (Resin) | .460 gallons (59 oz) |

| Part B (Hardener) | .630 gallons (81 oz) |

| Part C (Water) | .406 gallons (52 oz) |

Upcoming Events: Get Certified!!

Class on September 15-16th

Become a certified Citadel Products installer by attending a training seminar. Citadel training

sessions are typically held on a monthly to bi-monthly basis depending on the number

of interested parties. We always welcome new installers, but even if you have been to a

previous session, consider that Citadel continues to introduce new and innovative products.

Register today to find out more about the benefits and uses for revolutionary products including polycuramine, Hydrostops, and hybrid polymer sealants.

Please let us know if you are interested in attending a training seminar, we

would love the opportunity to showcase both our current products and any new products and

installation techniques!! Click here for registration information

Tech Tip: Citadel Go-Zirra 2400 & 1800 Planetary Grinder

The Citadel Go-Zirra 2400 (24") and 1800 (18") planetary grinder is an excellent choice for

small to medium size concrete preparation jobs. While offering a hefty 520 lbs. of optional

head pressure, (2400) and 355 lbs. (1800) this machine is still nimble enough to be easily

loaded and unloaded at the jobsite. Its power to weight ratio offers fast production rates and

aggressive profiles for use with any coating systems.

|

FEATURES:

- Variable speed control

- 100% steel gear driven technology - no belts to break or wear out!

- Flexible mounting heads follow the contour of the substrate being prepared

- Magnetic diamond tooling attachments make changing pads fast and easy

- Can be used for coarse grinding, polishing, sanding, coatings removal, or maintenance

- Disassembles for easy transportation or repairs

|

CONTACT YOUR CITADEL REPRESENTATIVE FOR PRICING INFORMATION!

|