What are the best temperatures for coating concrete - and summertime installation tips

2018-05-16

A Midwestern friend of mine jokes, “We have two seasons: winter and construction.” He was talking about road construction, but anyone in the industry can feel the uptick in business: weather has warmed, and we are coming into the busy season for construction – including garage remodels and other concrete coating projects.

But what are the best temps for coating concrete? And how do you install when it is hot and humid?

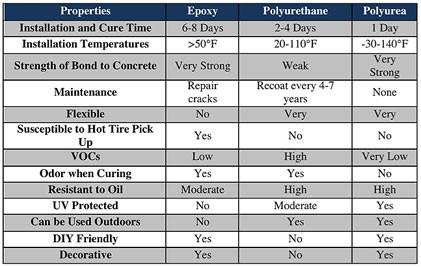

The best temperatures for coating concrete depend on your material. A quick comparison of the most common coatings is as follows:

Epoxy requires that installation take place over 50?F. Polyurethane is applicable at a wider temperature range, 20?-110?F. Polyurea has the greatest workable range, from as low as 30? below 0 to 140?F.

Now that warm weather is here, a few precautions can keep work going smoothly, even as rising temperatures cause coatings to cure more quickly than usual.

#1: Choose hot weather-friendly products.

Look for coatings that are formulated by the manufacturer to cure more slowly.

For example, PG-100 polyaspartic polyurea is available in a “slow” version formulated for temperatures ranging from 40-100° F. RG-80x polyaspartic polyurea, a UV-stable topcoat, can be obtained in “slow” (50-90° F), and “super slow” (90-100° F+) formulas. (Both materials have “fast” versions appropriate for cold weather applications.)

The same goes for your primer or basecoat. Polyurea-350 primer uses proprietary adjustable cure rate technology to maintain its longer “open time” capabilities across temperatures, including a “summer” (70-100° F) blend.

Always check with your coatings manufacturer about temperature and humidity limits before coating—click here to schedule a call with Citadel’s coating experts.

Tip #2: Keep your materials cool.

Starting with warm product out of the bucket will affect your application. Additionally, for polyaspartic coatings, humidity acts as an accelerator and shortens pot life and cure time as well.

Keep your products inside/in the shade, and out of direct sunlight.

Chill or ice your material so it’s cooler than outside temperatures. (Some contractors use refrigerated trucks to store materials during the summer.) Or, mix small batches and place the material faster.

Tip #3: Add solvent to thin coatings.

You’ll want solvents with a medium-to-slow evaporation rate.

Always refer to the manufacturer’s technical data sheets for your products for acceptable solvents and amounts to add.

Bonus Tip #4: Ask an expert.

To get your questions answered on your hot and humid weather coating project, click here to schedule a no-obligation call with our experts, who are happy to help. Stay cool this summer!

Latest News

How to Maintain Your Concrete Grinder

Gain Customers and Referrals in 4 Easy Steps

Ready for the Summer Rush? 4 Ways to Prepare

6 Cold Weather Safety Tips for Installers

How to Remove Salt Stains from Concrete

Testimonials

Every time I call I get to talk to someone, and I always have an answer within 20 minutes. That's awesome.

Client: Terry C.